Have you noticed that none of the windows in our house have trim? No? Maybe? Ok, maybe it’s just me! I notice it constantly!

One of my dream updates that I want to do in our townhouse is to trim out all of the windows. Since our townhouse is a builder grade home, the windows don’t have trim on them. And without trim, the windows look a little “unfinished” in my opinion.

Since we moved in, trimming the windows hasn’t really been at the top of our to-do list. But, once we decided to renovate the powder room, the smallest window in the house moved to the top of the list as the first window to get trim!

If you’re new to the blog, we’re right in the middle of renovating our powder room. Last week I shared the design plans for the space and earlier this week I shared the first DIY project.

Today, I’m sharing the next DIY project – modern craftsman window trim.

I love the look of craftsman style trim in a modern classic home. The clean lines and pretty crown pieces make the trim stand out while not being too flashy. Simple, clean, and bold – that’s why I love craftsman style trim.

Now it’s time for all the DIY details.

DIY Modern Craftsman Window Trim

This post contains affiliate links for your convenience. For more information, see my disclosures here.

Materials

- 1×4 Pine Boards*

- 1×6 Pine Boards*

*We used plywood for our trim because that’s what we had on hand from our shiplap project. It would have been easier to use pine boards

- 1×2 Pine Board

- 1×3 Pine Board

- Wood Glue

- 1.5” Brad Nails

- Wood Putty

- Caulk

- Primer

- White Semi-Gloss Paint

Supplies

- Miter Saw

- Jigsaw

- Brad Nailer

- Tape Measure

- Sandpaper (80 Grit & 120 Grit)

- Paint Tray

- Paint Brush

- Paint Roller

Planning Phase

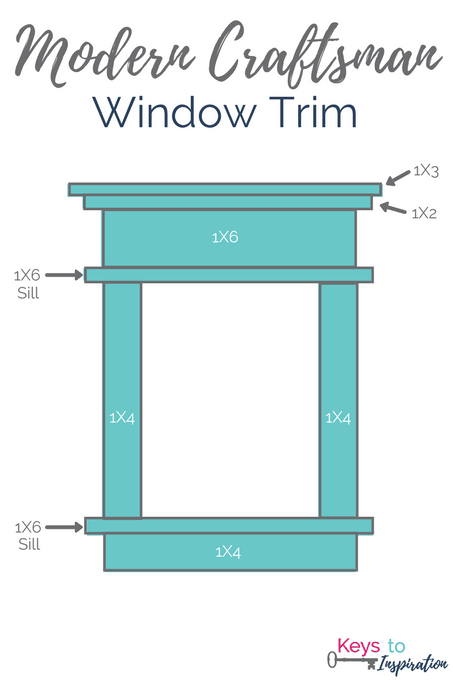

Before we started any actual DIY work, we created a sketch plan of the craftsman style trim that we wanted to build.

To create the modern craftsman trim for the window, we decided to use 1×4 boards, 1×6 boards, and 1×2 and 1×3 boards.

The trim is made up of a few different pieces.

- Apron (bottom) – 1×4 board

- Lower Sill – 1×6 board

- Sides – 1×4 boards

- Upper Sill – 1×6 board

- Header – 1×6 board

- Crown – 1×2 board and 1×3 board

- Casing – 1×4 boards custom cut (these will be explained later)

Once we had a plan, it was time to start building.

Building Phase

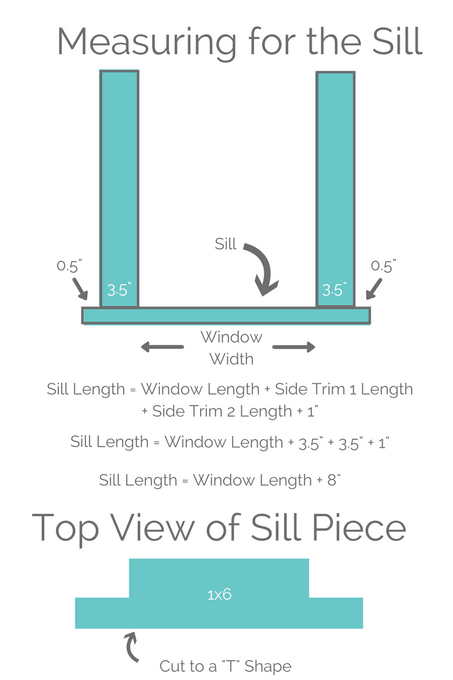

First, we built the lower and upper sills. The sills were created using 1×6 boards.

To get the correct length of the sills so that they extended past the side trim pieces, we first measured the window. Then, we added the width of the side trim pieces (3.5” each). FInally, we added an additional 1” so that the sill would extend past the side trim 0.5” on either side.

Sill Length = Window Width + Side Trim 1 Length + Side Trim 2 Length + 1”

We used the miter saw to cut the 1×6 boards to the correct sill length.

The sill pieces have to fit inside of the window jamb. So they are actually cut into a “T” shape.

We measured the inside of the window and marked where the 1×6 board should be cut to create the “T” shape. Then, using a jigsaw, we cut out the sides of the sills so that they would fit into the window jamb.

For our specific window, we trimmed down the 1×6 board to 5” deep for the lower sill and 4” deep for the upper sill. That way the sills wouldn’t stick out too far into the powder room.

To install the sills, we put some wood glue on the back of the boards used the brad nailer with 1.5” brad nails to attach them into place.

Next, we created the casing inside the window. The casing sits inside the window jamb between the lower and upper sills. To make the casing, we used two 1×4 boards that were cut to the depth of the window jamb.

We wanted these boards to have their edges flush to the outside wall so that the side trim pieces could cover them.

We used the miter saw to cut the casings. The length of these pieces was the distance between the top and bottom sills. Then, using some wood glue and the brad nailer, we attached the casing pieces to the inside of the window jamb.

Next, we measured for the side trim pieces. The length of these pieces was the distance between the top and bottom sills. We cut the 1×4 boards using the miter saw and attached them to the front using wood glue and the brad nailer.

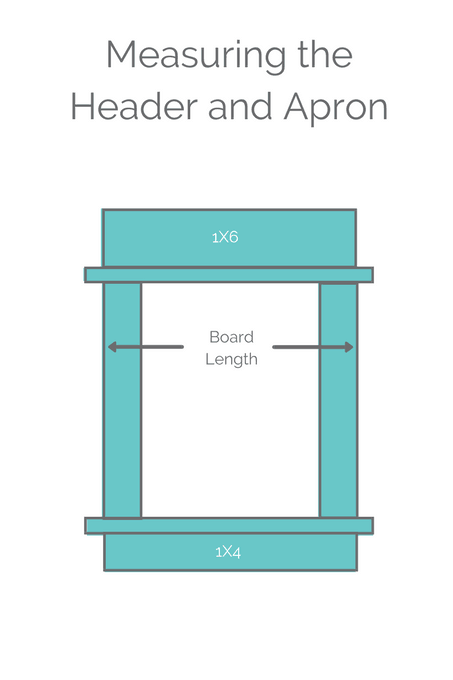

Once the side pieces were up, it was time to create the apron and the header pieces. Both of these pieces were the same lengths. To find the length for these pieces, we measured the distance between the outsides of the side trim pieces.

Once the boards were cut, we attached the 1×4 apron board underneath the lower sill and the 1×6 header piece above the upper sill using wood glue and the brad nailer.

For the crown pieces, we used a 1×2 board and a 1×3 board stacked together. This stack was then attached to the header piece.

(Here’s a little preview of the primed trim)

Finishing Phase

After everything was installed, we used wood putty to fill in all of the nail holes. Then, we used caulk to fill in the seams between boards and the gaps between the trim pieces and the wall. This made everything look seamless and built in.

Once everything was dry, we sanded all of the trim twice. First with 80 grit sandpaper and then with 120 grit sandpaper.

Finally, it was time to prime and paint!

First, we coated all of the trim with primer. After that was dry, we painted the window trim with 2-3 coats of white semi-gloss paint.

To get an even coverage, we used a brush to get into the smaller areas. Then, we used a roller on the outside surfaces of the trim to create a smooth painted finish.

Then, once the trim was dry, we stepped back and admired the finished craftsman window trim!

Psst: There’s a sneak preview of the art in the finished room!

I was so excited to finally see how the craftsman style trim would look on our windows. And let me tell you, I’m loving it! I can’t wait to do the rest of the windows. But for now, I get all excited whenever I get a glimpse of the trim in our powder room.

The powder room window is actually a square, so adding the craftsman style trim makes the window look more rectangular. And now, the window actually looks larger making everything seem brighter.

I can’t wait for next week when I’ll be sharing the full Powder Room Reveal! Stay Tuned!

DIY Modern Shiplap Wall Treatment

DIY Modern Craftsman Window Trim (You’re Here)

Fresh & Modern Powder Room Reveal

I have an authentic Craftsman house and I think your trim looks better than mine.

Thanks Kathleen! I will definitely be telling my husband, because he’s the handy one around here. He will love that!

So glad to have you here on the blog 🙂

>> Christene

This is super cool! Looks fantastic! Hoping to buy a house at the end of the year. I’m pinning this and crossing my fingers. I love your style. 🙂

Thanks for the kind words Jen! That’s so excited that you are looking to buy a house in the future. Thanks for pinning! 🙂

>> Christene

Beautiful! I’d love to steal this design for our house. Did you match the crown molding and baseboards, as well?

We actually did not. There is no crown in our house because it’s a builder grade home — pretty basic. We do have baseboards, and they’re minimal. They don’t match exactly, but they are both white and it honestly doesn’t bother me.

Thanks for stopping by the blog

>> Christene

I am loving this! My husband and I built ours, but having trouble finishing up. We can see the texture of the wood coming through the paint, and i can’t get a smooth finish. I also think we used the wrong primer Killz latex (so I’ll be removing the paint and priming it with your suggestion) Can you tell me which size roller I should get ? The link directs me to a main page on amazon with a lot of different options

Thank you!

I normally use the smaller foam rollers, not the really big rollers. The bigger ones are better for walls. The smaller “mini” rollers should work best for what you are doing.

>> Christene

Hi there – I’m thinking of making these casings, but had a question about the header. For the one thing piece at the bottom and the two thin pieces on the top, how much do they extend past the casing? It looks like two of them are the same length as the sill, a half inch on either side. The top.piece, is that a full inch entended on each side?

Thanks!

Yes I think I have a full inch on each side. There’s more info in that workbook too if you are curious.

>> Christene

Hello! Thank you so much for the detailed plans! I was wondering about the lengths that you used for the top section. How far our passed the header was the upper sill (1×6)? Then the 1X2 is the same length as the upper sill (1×6) correct? Finally, how long is the 1X3 from the 1×2?

Thank you for your help!

Hey Dani,

I actually did an updated post on how to do craftsman window trim. You can find it here. In that post, I share a detailed workbook that should help you with the spacing.

https://www.keystoinspiration.com/how-to-install-easy-craftsman-window-trim/

Hope this helps,

>> Christene

DIY is awesome! It allows you to create a piece of artwork on your own.

Thank you for your FANTASTIC directions. I will be doing this over the Christmas holiday!

Omg I LOVE THIS and is so helpful!!!! Thank you!!!! Would love to know the color of the wall you chose!! It’s exactly what I’m looking for!!

Thanks! The color of the wall is Valspar Hazy Stratus.

>> Christene

Great piece. This is something my wife and I are interested in doing. I love the color on the walls . Do you happen to know the color? Thank you.

Thanks! The color of the walls is Valspar Hazy Stratus.

>> Christene